Guide to Engaging China Injection Molding Suppliers

Well, the major meeting has just concluded. your new product is a go, the timeline is aggressive, and the budget is, let’s say, constrained.. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

You nod, of course. It seems sensible at first glance. Savings can be substantial. But your mind is already racing. You’ve heard all the horror stories, right? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

However, here’s the reality. Sourcing plastic mold company doesn’t have to be a gamble. It’s a project, just like any other. And its outcome hinges on the approach you take. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Ignore the nightmare anecdotes. Let’s go through a step-by-step guide to succeed.

Initial Step: Prepare Your Information

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. You can’t expect a factory on the other side of the world to read your mind. Sending a vague request is like asking a builder to quote you for “a house.” The replies will range from absurdly low to exorbitant, none of which help.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This package is your project’s foundation.

What belongs in your RFQ?

First, your 3D CAD files. These are non-negotiable. Use standard formats such as STEP or IGS to ensure compatibility. This is the master blueprint for your part’s geometry.

But 3D isn’t enough. Include precise 2D engineering drawings. This details critical info missing from the 3D file. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. Any seal surfaces or critical hole sizes must be clearly labeled.

Next up, material. Don’t just say “Plastic.” Don’t even just say “ABS.” Be explicit. If you need SABIC Cycolac MG38 in black, say exactly that. Why? Because plastic grades vary by the thousands. Defining the exact material guarantees the performance and appearance you designed with plastic mold injection.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

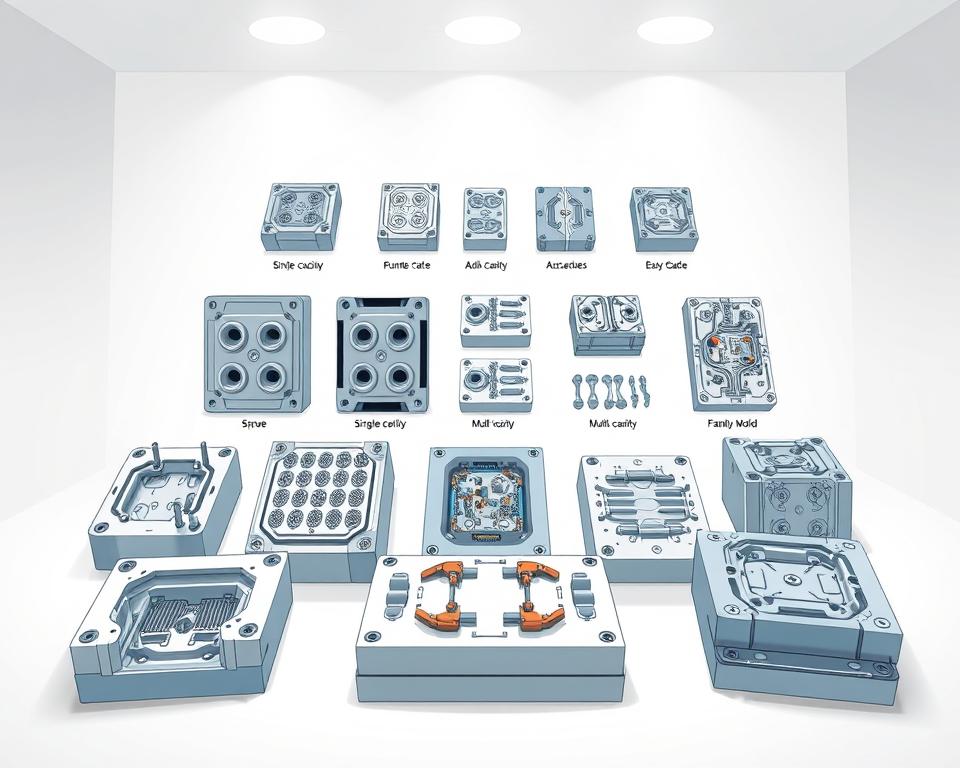

Lastly, add your business data. State your EAU. You must specify if it’s a 1K-part tool or a 1M-part production run. Cavity count, tooling cost, and per-unit pricing depend on volume.

The Great Supplier Hunt

Okay, your RFQ package is a work of art. who will you target? The web is vast but overwhelming. It’s easy to find a supplier; it’s hard to find a good one.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They offer breadth but not depth. Use them to build a shortlist, not the final list. Narrow your pool to about a dozen promising firms.

Still, you must dig deeper. Perhaps hire a local sourcing specialist. They do cost extra. But a reputable agent brings pre-screened factories. They handle local liaison and oversight. On your first run, this is like insurance. Think of it as insurance for your project timeline.

Another tactic: trade exhibitions. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. Meeting onsite is unbeatable. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. And don’t forget the oldest trick in the book: referrals. Ask other project managers in your network. A recommendation from a trusted peer is often worth its weight in gold.

Shortlisting Serious Suppliers

After firing off that RFQ to a broad pool, estimates roll in. Some prices will undercut logic, others will shock you. Your job now is to vet these companies and narrow it down to two or three serious contenders.

How to proceed? It’s a bit of an art and a science.

Begin with responsiveness. Is their turnaround swift and concise? Can they handle detailed English exchanges? But the key: do they probe your RFQ? The best firms will question and suggest. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” That’s a huge positive sign. It proves their expertise and involvement. A “Sure, no issues” vendor often means trouble.

Then confirm their machinery specs. Request their machine list. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Next up: the factory audit. This is not optional. Just as you interview hires, audit suppliers. You can travel or outsource a local inspector. They dispatch an on-site auditor for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s a tiny cost for huge peace of mind.

From Digital File to Physical Part

After picking your vendor, you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Now the process kicks off.

The first thing you should get back after sending your payment is a DFM report. Design for Manufacturability (DFM) is essential. It’s the engineering critique for moldability. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. A thorough DFM is a sign of a professional operation. It becomes a joint effort. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. In a few weeks, you’ll see “T1 samples are on the way.” These are the very first parts off the new tool. It’s your test of success.

Expect T1s to need tweaks. That’s standard process. You’ll find minor defects, off-spec dimensions, or finish issues. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. It could require several iterations. Build buffer time for sample iterations.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is your golden sample. You ratify it, and it becomes the quality yardstick for production.

Crossing the Finish Line

Getting that golden sample feels like the end, but it isn’t. Now you’re entering the mass production phase. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. Typically, this means a pre-shipment audit. Use a third-party inspector again. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. You receive a full report with images and measurements. After your approval, you release the shipment and final funds. This audit shields you from mass defects.

Lastly, plan logistics. Clarify your Incoterms. Are you on FOB terms, where they load and you take over? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? These choices hugely affect landed cost.

China sourcing is a long-haul effort. It hinges on strong supplier relations. See them as collaborators, not vendors. Transparent dialogue, respect, and process discipline win. No question, it’s demanding. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re set to succeed.